[ad_1]

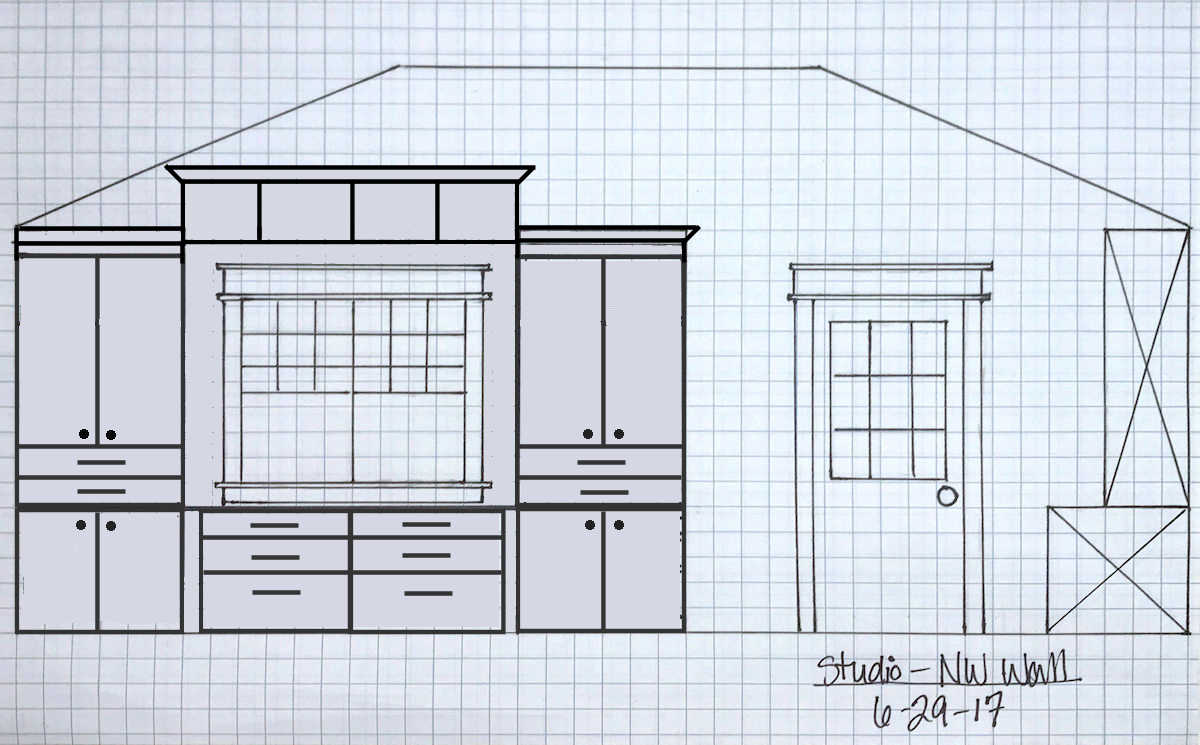

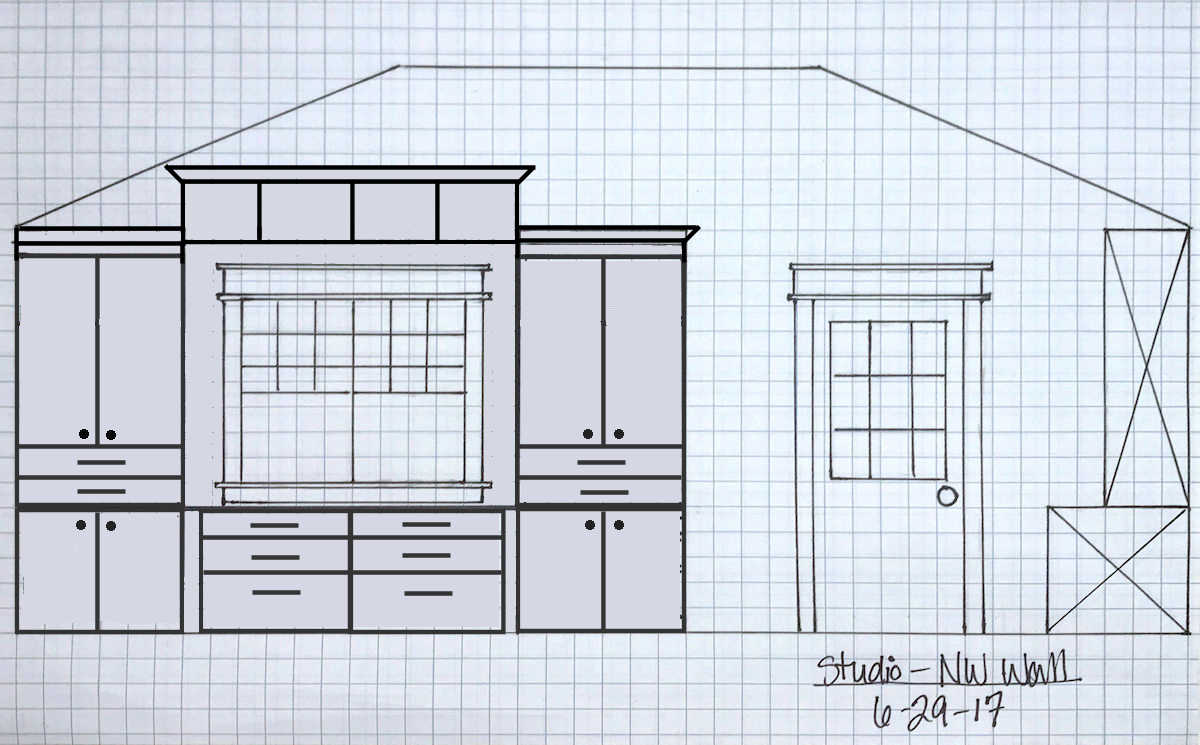

I did it! I built a cubby bridge on my studio office area cabinets yesterday and I couldn’t be more thrilled with how this section turned out! As a reminder, here is the goal…

And at the start of the day yesterday, the cabinets in that area of the room looked like this…

The original cabinets (white parts) are IKEA sectional cabinets and I am in the process of customizing them. This is only a multi-post project, so I’ll link previous posts below this one.

When it comes to building the cubby bridge, my first thought is to build it in the carport, then bring it inside and screw it to the sides of the cabinets. But I work alone. For those new here, my husband Matt has MS and is completely Couldn’t help myself with projects. And although there are many people who are willing to help me, I hate bothering people for things like this. Additionally, I am very independent and thrive on figuring out how to get things done.

So that’s the challenge. How can I build a cubby bridge and then climb it myself while trying to screw it up? The answer? I will not! Instead, I decided to build it in place. That seemed too much.Work smarter, not harder“I have a solution. Here’s how I did it…

First, I measured and marked where I wanted the bridge to be attached to the side cabinets and attached a piece of scrap wood to the side of the cabinet along the top edge of the board along the line I just marked. This ledger board is temporary and I attached it using three 1.5-inch 16-gauge nails.

Then I repeated the process on the other side.

With my makeshift ledger boards, I measured and cut a piece of 3/4-inch plywood for the bottom of the cubby bridge. It took a couple of tries to get it to fit just right, but on the second try, it fit perfectly between the side cabinets and rested on the ledger boards. You’ll see a slight bend in the middle, but I’m not worried about that. It will be corrected later in the construction process.

After mounting the part, I removed it and drilled three pocket holes on each end. These pocket holes are on the top of the board, not the bottom. The bottom is visible when standing in the room and I don’t want visible pocket holes and I don’t want to fill pocket holes in visible areas.

To drill the pocket holes, I used my Kreg Pocket Hole Jig. This is what I have (affiliate link), and it’s worth every penny. If you like to build furniture or cabinets, this tool is a must have!

So again, I drilled three pocket holes on each end of the piece, making sure I drilled the holes at the top of the piece.

At this point, I brought my scaffolding to make the whole construction process even easier. This is what I have (affiliate link — also available at Home Depot), and another thing I recently purchased that I wonder how I lived without for so long!

So standing on the scaffolding, I put the piece of plywood back on the temporary ledger boards, with the pocket holes facing up, and I screwed the piece to the side of the tall cabinets.

After saving it, it looked like this. The bow in the middle is still there, but I’m not worried about it at this point. I wanted to make sure it was flush with the trim at the top of the window.

After I made sure it was level, I removed the temporary ledger boards. That left three nail holes on each side that I had to fill and sand, but I’m okay with that. Us solo DIYers have to do what it takes, and filling and sanding six small ink holes is a small price to pay for doing the job myself.

Next, I used my table saw to cut the pieces for the ends. I attached these by nailing them into the plywood on the side of the side cabinet from the inside of this side piece (ie, in the direction my nail gun was pointing down).

Then I nailed through the bottom piece of plywood and into the edge of the side piece as well.

After repeating on the other end, I was ready to cut the back to fit inside the two end pieces. This is where the bow on that bottom board is corrected. You can see the back is put in place on the bottom and the bow on the bottom board is still visible.

To secure that back piece, I first nailed it through the side pieces into the edge of the back piece.

After repeating on the other end, I nailed the bottom piece into the bottom edge of the back piece.

This took care of the bow and fixed the bottom piece of plywood. At this point you can see that there is no gap between the two pieces.

To be clear, other than the six pocket screws holding the bottom in place, I built the whole thing using 1.5-inch 16-gauge nails. I have full confidence that these nails will hold. The kind that go in the nail gun are tough and really grab into the wood. If you’ve ever built something using these nails and had to take them apart, you know how strong they are. But if you’re less confident than I am about how well the nails will hold, you can always use wood glue in addition to the nails or even add more pocket holes to hold the pieces together.

Next, I cut and attached the top piece, nailed the three sides that sit on the side piece and the back piece. I nailed the top and into the edges of those three pieces. At this point, it’s really starting to look like something!

And the last step of basic construction for the cubby bridge is to cut and attach the dividers. I cut them out using my table saw and then attached them like the other pieces.

After measuring and marking for the placement of these divider pieces, I nailed the bottom piece into the bottom edge of the divider pieces.

Then I nailed the top and edges of the divider pieces.

And with that, the basic build is complete! This cabinetry section will need a lot of trimming and finishing to get it to look like I envisioned in my mind, but I’m good to go!

I want each of you to see it in person. Pictures don’t do it justice. This section of cabinets took that long, wide wall from looking small and dwarfed, to looking substantial enough to hold its own against that massive wall. Sometimes, more precisely is better! 😀 And I think, when all is done, it will look like custom cabinets now.

So stay tuned, because coming up next, I’ll be all trimmed and ready for primer and paint. I’m so excited to see this section finished soon!

Addicted 2 Decorating shares my DIY and decorating journey as I renovate and decorate the 1948 Fixer Upper that my husband, Matt, and I purchased in 2013. Matt has MS and is unable to do physical activity, so I do most of the housework myself. You can learn more about me here.

[ad_2]